MATERIAL DIVISION BRAZING MATERIAL

Daishin Bronze

Brazing alloy providing stable brazing at high temperature. There are two main types; one with nickel (Ni) for a wide range of applications, and one with tin (Sn), which has a higher fluidity.

- MECHANICAL PROPERTIES

-

The table can be scrolled horizontally.

Type Tensile

StrengthElongation Melting

TemperatureCompositions Remarks Ni-Type 32kg/mm2 36% 905℃~910℃ Cu/Zn/Ni/Si Specified mechanical strength is based on 2.0 mm dia. wire. Sn-Type 32kg/mm2 27% 880℃~905℃ Cu/Zn/Sn/Si TS-Type 32kg/mm2 27% 885℃~900℃ Cu/Zn/Sn/Si

- ADVANTAGES

- ・Inexpensive.

・Shows superior fluidity and superb lustrous finish.

・Nickel or tin in the alloys reduces burnout of zinc, eliminating brazing problems such as blowholes or pinholes.

・High mechanical strength.

- APPLICATIONS

- Automobile body, frame and various parts, electric parts, steel furniture, hydraulic machine parts, brazing for super hard alloy tools, stainless steel, tool steel, malleable, case iron, copper and copper alloy brazing, brazing for different types of parent metals such as copper and nickel alloy, etc.

- SIZE AVAILABLE

-

The table can be scrolled horizontally.

Various rings, length are available.WIRE DIA. (ø) LENGTH&FORM 1.2

1.6

2.010kg/reel

or

1000mm. cut

(20kg/carton box)2.6

3.0

3.21000mm. cut

(20kg/carton box)

MIG Brazing Wire (DIL350)

Copper alloy wire for light gauge drawn steel welding.

- MIG BRAZING WIRE DIL 350

- DIL 350 wire is special alloy developed as the material for MIG brazing, which is made of copper as the base metal with silicon and manganese, generally named silicon bronze or MIG brazing wire. Our DIL 350 wire is especially applicable for light gauge steel sheet for the automobile industry. The produces very smooth beads finish. DIL 350 wire utilizes the eutectic point of the brazing material in order to reduce the heat distortion of base metals as much as possible. The braze metal melting temperature is very low and bead height is very small. DIL 350 has very good grind ability since the hardness of the DIL 350 is controlled. With attention to the root gap and joint shape, DIL350 is applicable to lapped fillet welding, butt-welding, horizontal fillet welding and edge welding with all welding positions.

- MIG WIRE DIL 350 SPECIFICATION

-

The table can be scrolled horizontally.

COMPOSITION 3-4% Si, 0.9-1.2% Mn,

0.2% active metals, balance CuTENSILE STRENGTH 35~45 kg/mm2 ELONGATION 33% HARDNESS Hv 110~130 WIRE DIAMETER Φ0.8 Φ1.0mm (±0.02mm) WEIGHT 10kg/reel, 15kg/reel, 100kg/pack reel WELDER MIG Pulse Welder

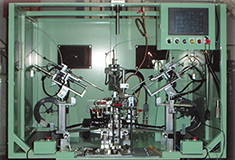

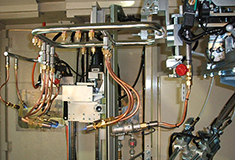

- FULLY AUTOMATIC WELDING SYSTEM

- We, Daishin Industrial Co., Ltd. specialize in the design and manufacture of automatic systems. We have developed a heat distortion correcting system for light gauge steel welding, which has been proved by many results and experiences. Our fully automatic brazing machine using DIL 350 is integrated with a sensor to monitor the teaching locus and to check the orbit correction value, which occurs by welding distortion at the welded area. This system is also available for the correction of precision error while setting up the work piece.

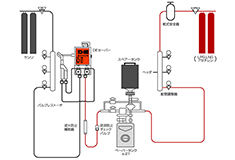

- * A robot application is sketched below. DIL 350 can be applied on the robot and N/C machine.

-

FULLY AUTOMATIC WELDING SYSTEM

1. Argon gas 2. Power supply 3. Wire feeder 4. Robot 5. Welding torch 6. Robot controller

* A multiple arm robot fixed on a ceiling is available besides the above.

- MIG BRAZE WELDING METHOD

- MIG brazing is one of the joining methods for light gauge steel (SPCC, SS41P, etc.) without melting the base metal using a MIG welder with copper alloy as the wire material wound on a reel. For this welding method, only argon gas is used.

Daishin Aluminum Flux-Cored Wire (DCW)

Non-corrosive cesium flux-cored 4047 aluminum brazing alloy, highly recommended for automated brazing applications.

- Composition of aluminum brazing material (AL4047)

-

The table can be scrolled horizontally.

Si(%) Fe(%) Cu(%) Mn(%) Mg(%) Zn(%) Al 11.0~13.0 <0.8 <0.30 <0.15 <0.10 <0.20 Bal.

- Specifications of DCW

-

The table can be scrolled horizontally.

Flux-charged

percentageDiameter (mm)

of wireType and weight 28%, 32%

(Selectable)1.6, 2.0

(Selectable)Spool of 5kg

Daishin Aluminum Flux-Cored Rings (DCWR)

Formed ring version of DCW, these can be custom sized to fit any application (Diameter, gauge, weight).

- List of Silver Brazing(Mizuno Handy Harman,Ltd.)

-

The table can be scrolled horizontally.

Alloy Name JIS

StandardNominal Composition % Melting

Point ℃Flow

Point ℃Main use Ag Cu Zn Cd DIA-330 BAg-20 30 38 32 about 675 about 765 For padding, automotive parts DIA-435 BAg-5 45 30 25 about 665 about 745 Turbine blade, heavy electric equipment (motor parts) DIA-530 BAg-6 50 34 16 about 690 about 775 Turbine blade, heavy electric equipment (motor parts) DIA-520 50 50 about 780 about 880 Control equipment, for atmosphere brazing DIA-722 BAg-8 72 28 about 780 about 780 For electronic components, vacuum brazing DIA-825 85 15 about 780 about 840 For electronic components, vacuum brazing DIA-345 35 33 30 Sn2 about 655 about 740 Oil separator, versatile silver wax DIA-400 40 30 29 Sn1 about 660 about 710 Large refrigerator piping, radiator, large heat exchanger DIA-445 45 25 29 Sn1 about 665 about 700 Small brass parts, couplings, compressors DIA-487 48 28 19 Sn5 about 640 about 690 Brass products DIA-545 BAg-7 56 22 17 Sn5 about 620 about 650 Stainless steel tableware, decorative parts, control equipment, auto parts DIA-30N 30 34 35 Ni1 about 686 about 768 Compressor, stainless steel products DIA-35N 35 31 33 Ni1 about 680 about 757 Fulton tube, bundy tube, compressor DIA-44N BAg-4 40 30 28 Ni2 about 670 about 780 Carbide tools, stainless steel products in general, auto parts BRAZE 495 49 16 23 Ni4.5

Mn7.5about 680 about 700 Tungsten carbide, stainless steel products in general BRAZE 505 BAg-24 50 20 28 Ni2 about 660 about 705 Stainless steel products general, brass products DIA-25 25 30 23 22 about 595 about 703 Versatile silver wax. Valid for any iron, nickel, copper alloy DIA-340 30 23 20 27 about 600 about 670 Versatile silver wax. Valid for any iron, nickel, copper alloy EASY-FLO 35 BAg-2 35 26 21 18 about 605 about 700 Versatile silver wax. Valid for any iron, nickel, copper alloy DIA-440 40 20 14 26 about 616 about 665 Versatile silver wax. Valid for any iron, nickel, copper alloy EASY-FLO 45 BAg-1 45 15 16 24 about 605 about 620 Versatile silver wax. Valid for any iron, nickel, copper alloy EASY-FLO BAg-1A 50 15.5 16.5 18 about 625 about 635 Versatile silver wax. Valid for any iron, nickel, copper alloy EASY-FLO 3 BAg-3 50 15.5 15.5 16 Ni3 about 630 about 690 Carbide chips, stainless steel products DIA-47 46.5 15.5 15.5 15.5 Ni2

Mn5about 630 about 670 Cemented carbide tool DIA-348 38.0 32.0 28.0 Ni2 about 650 about 720 compressor

- List of Phosphor Bronze Brazing(Mizuno Handy Harman,Ltd.)

-

The table can be scrolled horizontally.

Alloy Name JIS

StandardNominal Composition % Melting

Point ℃Flow

Point ℃Main use Ag Cu P SIL-

FOS 2019.0~21.0 Rest 5.8~6.3 about 645 about 710 Brass parts (distributor), coupling SIL-FOS BCuP-5 14.5~15.5 Rest 4.8~5.3 about 645 about 800 Crimp terminal, brass parts, motor contact terminal, charger SIL-FOS 10 9.5~10.5 Rest 6.4~6.9 about 645 about 750 Brass parts, SIL-FOS 20 substitute, air conditioning piping F-6 BCuP-4 5.8~6.2 Rest 6.8~7.7 about 645 about 720 Air conditioning piping, brass parts, showcase SIL-FOS 5 BCuP-3 4.8~5.2 Rest 5.8~6.7 about 645 about 815 Air conditioning piping, refrigerator piping SIL-FOS 2 BCuP-6 1.8~2.2 Rest 6.8~7.2 about 645 about 790 Air conditioning piping, BCuP-3 substitute F-2 1.8~2.3 Rest 6.0~6.7 about 645 about 810 Air conditioning piping, BCuP-3 substitute, showcase SIL-FOS 1 0.8~1.2 Rest 6.5~7.1 about 645 about 820 Air conditioning piping, BCuP-6 replacement DIA-20P BCuP-2 0 Rest 6.8~7.5 about 710 about 795 Air conditioning piping, water heater, showcase

- PRODUCT

MACHINERY DEPARTMENT

MATERIAL DIVISION